classification of stone crusher

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Based on the mechanism and the type of forces applied crushers are basically classified into three types namely Jaw crusher, Cone crusher and Impact crushers. However, the performance of all the crushers according to specific areas of application is

More

(PDF) Design of Impact stone crusher machine

2019.5.31 Abstract. Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries.

More

Table 3602/1 CRUSHED STONE BASE AND SUBBASE:

2021.3.4 Table 3602/1 CRUSHED STONE BASE AND SUBBASE: MATERIAL REQUIREMENTS Material TYPE OF MATERIAL Characteristic G1 G2 G3 Parent Sound rock from an approved Sound rock, boulders Sound rock, boulders or Material quarry, or clean, sound mine or coarse gravel coarse gravel rock from mine dumps, or clean sound

More

The Complete Guide to Primary Crushing,

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has

More

Effect of crushing mechanism on the shape properties of

2022.1.1 Granitic aggregate crushed by two different two stage crushing sequence i.e., (i) primary crusher being jaw crusher followed by a secondary cone crusher (J-C) (Fig. 1 a) and (ii) primary crusher being jaw crusher followed by secondary jaw crusher (J-J) (Fig. 1 b) was considered for the present study and crusher details are presented in Table 1 ...

More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 All rock crushers can be classified as falling into two main groups. Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the material. Jaw crushers, gyratory crushers and cone crushers operate according to the compression principle.

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 Based on the mechanism and the type of forces applied crushers are basically classified into three types namely Jaw crusher, Cone crusher and Impact crushers. However, the performance of all the crushers according to specific areas of application is the major point of concern in the research field [2].

More

(PDF) Design and Performance Evaluation of a

2021.10.7 Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher.

More

Crushers and Their Types – IspatGuru

2015.4.3 Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher. The primary crusher

More

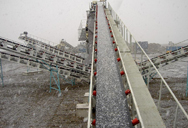

Stone Crusher Plant Design: Best Practices for Efficient

2023.2.28 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing production ...

More

Classification of dimension stone wastes Environmental

2012.2.1 Purpose For countries in which the stone industry is well developed, opposition to quarry and plant waste is gradually increasing. The primary step for waste control and environmental management is to define the problem of concern. In this study, natural building stone wastes were classified for the first time in the literature. Methods

More

Placing stone crushers in ‘green’ category will create a huge ...

2023.12.28 The stone crusher sector is an obvious source of PM pollution and cannot be allowed to downgrade to the green category from the existing orange one. There are numerous cases that can be highlighted to provide an overview of the problems with stone crushers. One such NGT case (original application number 23/2017 (EZ)) dated March

More

Classification of Sand Washing Machine and its Working

Classification of Sand Washing Machine and its Working Principle and Characteristics As a kind of sand making equipment, sand washing machine is widely applied to gravel pits, mining, building materials, transportation, stone industry, water conservancy and hydroelectric power, concrete mixing plant and is used for washing, grading and

More

Placing stone crushers in ‘green’ category will create a huge ...

2023.12.28 The stone crusher sector is an obvious source of PM pollution and cannot be allowed to downgrade to the green category from the existing orange one. There are numerous cases that can be highlighted to provide an overview of the problems with stone crushers. One such NGT case (original application number 23/2017 (EZ)) dated March

More

Primary Crusher vs. Secondary Crusher: Understanding Their

2023.2.28 The primary crusher’s function is to reduce the size of the rock or stone for easier handling and transportation. The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material between two surfaces. The jaw crusher works by moving the material between a fixed and a moving plate.

More

Mengenal Fungsi Dan Jenis Stone Crusher

2024.1.31 Fungsi Stone Crushers. Fungsi Stone Crushers. Salah satu fungsi utama dari stone crusher bisa dirasakan pada dunia industri pertambangan serta konstruksi. Berikut adalah berbagai macam fungsi yang dimiliki oleh alat penghancur batu di kedua bidang tersebut. 1. Menghancurkan Material.

More

(PDF) Design of Impact stone crusher machine - ResearchGate

2019.5.31 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well graded with 1.89 coefficient of ...

More

Dhanashri Stone Crusher Pune, Maharashtra - The

Dhanashri Stone Crusher is a 18 years 5 months old Partnership Firm incorporated on 23-Nov-2005, having its registered office located at Gat No 112, Bhavadi Road, Wagholi, Pune, Maharashtra. The major activity of Dhanashri Stone Crusher is Manufacturing, Sub-classified into Other manufacturing and is primarily engaged in the Manufacture of ...

More

Jaw Crusher Explained - saVRee

The strict definition is ‘the action of taking a material, specifically mineral ore, and reducing it to minute fragments or particles’. This is typically achieved in several stages of a detailed and professional mining operation. Jaw

More

What’s The Stone Washing Machine? - Eastman

2022.8.15 If you want to know how to select suitable stone washing machines for your project, please contact our engineer for help. sales@jxscmine. +86-13879771862. contact us. The stone washing

More

5 Types Of Stone Crushers Application and

The hammer mill rock crusher can be used not only for crushing plant, sand making plant, it also can replace cone crushers in mining plant. The types of stone hammers crushers: single-stage hammer crusher, high-efficiency

More

Crushed Stone Sizes Explained: Your Complete Guide

Practical Applications of Different Crushed Stone Sizes Uses of Fine Stone Dust. Due to its excellent compaction capabilities, fine stone dust is primarily used as a base material for paving blocks, patios, and pathways. Applications of #8 Stone #8 Stone is widely used in landscaping to decorate and create smooth walking paths.

More

hydro classifier silica sand classification Stone Crusher

Hydro Classifier Silica Sand For Sale, Price – Gold Ore Crusher. small size screw sand washer; sizing hydraulic classification such as hydro cyclones, This entry was posted in Uncategorized on April 20, 2013 by admin .

More

classification of stone crusher - shibang-china

The worlds largest stone crusher manufacturers, specializing in the production of jaw crusher, stone crusher, counter-attack crusher, impact crusher, crusher machine ... AP-42 Section 11.19.2 Crushed Stone Processing and Pulverized ...

More

Stone crusher classification and crusher foundation choose

2024.3.6 Stone crusher classification and crusher foundation choose introduction. 2024-03-06. Crushers are essential equipment in the mining, construction, and aggregate industries, tasked with breaking down large rocks into smaller, more manageable pieces. The effectiveness of a crusher depends not only on its classification but also on the

More

The Complete Guide to Crushed Stone and Gravel - Gra-Rock

2019.11.11 Crushed stone often has an angular and jagged edge because of the crushing process. Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and wear of being exposed to running water. Unlike crushed stone, gravel is usually sold and used in its natural state.

More

Gravel and Crushed Stone Types, Sizes and Grades

It has a broader color spectrum than crushed stone and is lighter and often less expensive. Crushed gravel can range in different sizes too and is often used for driveways, paths, and decorative purposes. It commonly ranges from 0.63″ to 1.26” in diameter and is commonly sold by the ton or truck-load.

More

Gravel Size Chart, Crushed Stone And Rock Sizes, Uses, Grades

2023.7.21 Gravel and Rock Sizes and Grades. Crushed rocks and stones are graded according to the size or diameter of individual stones. The name of each grade may differ depending on your location and can even vary from state to state, so you will always need to check with your supplier, but in general, grading sizes go from 1 to 10 plus several

More

Crusher, Crusher Equipment, Crusher Machine, Crushers for

2024.5.11 Crusher Classification. Type of Equipment: Jaw Crusher, Cone Crusher, Mobile Crusher, Stone Crusher: Degree of Crushing: fine broken, medium broken, coarse broken: Application Area: ... Crusher is also called stone crusher, rock crusher, gravel equipment, it is the machine that the exclusive compound content which the grain size

More

Understanding Aggregate Crushers: Types, Function, and

2023.9.2 The most common types of aggregate crushers are: Jaw crushers:These crushers use a fixed jaw plate and a movable jaw to reduce the size of the feed material. They are ideal for primary crushing. Impact Crushers:Impact Crushers use a high-speed rotor and hammers to hit the incoming material and break it into smaller pieces.

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing. Right from hard stones to delicate minerals, stone can incorporate slag ...

More

Table 3602/1 CRUSHED STONE BASE AND SUBBASE:

2021.3.4 Table 3602/1 CRUSHED STONE BASE AND SUBBASE: MATERIAL REQUIREMENTS Material TYPE OF MATERIAL Characteristic G1 G2 G3 Parent Sound rock from an approved Sound rock, boulders Sound rock, boulders or Material quarry, or clean, sound mine or coarse gravel coarse gravel rock from mine dumps, or clean sound

More

Methods of stone crushing - News of Joyal Crusher

There are several ways to apply force to crushing machinery. A squash. Place the material between the two extrusion surfaces (Figure a). After applying force, the material will be broken due to its compressive stress reaching the limit of compressive strength. Jaw crushers and cone crushers are mainly using this method.

More

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to two basic types, crushers and grinders. Industrial crushers are the first level of size reducer; further granularization ...

More

Mahadev Stone Crusher Charkhi Dadri, Haryana - The

Mahadev Stone Crusher is a 6 years 3 months old Partnership Firm incorporated on 06-Feb-2018, having its registered office located at Village Kalayana, Charkhi Dadri, Haryana. The major activity of Mahadev Stone Crusher is Manufacturing, Sub-classified into Other manufacturing and is primarily engaged in the Manufacture of other articles n e c .

More

Buildings Free Full-Text A Comprehensive Review of Stone

2023.7.21 The escalating demand for natural resources within the construction industry is progressing upward. At the same time, however, there is a great concern regarding the depletion of these resources. This review paper emphasizes the significance of utilizing alternative aggregate materials in concrete. Particularly, it aims to explore

More

What Machines Do Stone Crushing Plants Need? Fote

2024.3.1 2. Gyratory crusher. A gyratory crusher is one of the most in-demand primary crushers for stone crushing plants. It can process rocks, metal ores, granite, and other solid minerals of medium to high hardness. Gyratory crushers may be huge and capital-intensive, but they excel in high-capacity operations.

MoreArticle aléatoire

- tipo de equipo de cianuro para mineral de hierro en peru

- broyeur à machoires produsen di mumbai

- broyage fin et la flottation inverse

- prix du sable faisant la machine en inde

- fournisseurs de calcaire en kowet

- les fabricants de machines de fraisage micro

- Force De Concassage En Pierre Noire

- uae concasseur concassage

- daftar perusahaan gaz

- moulin à mouture ultrafine

- retraitement des résidus miniers d or

- criblage par voie humide et broyeur à boulets humide en Cameroun

- concasseurs plant de porcelaine

- equipement de traitement de l''or a vendre en Afrique du Sud

- écrasant la machine en allemagne

- equipement de meulage ultra fin

- cot de lusine de concassage de pierres en rajasthan

- ce qui est ciment de gypse

- matériaux de construction de bâtiments

- concasseur de pierre dans l uttar pradesh

- algérie broyeur à ciment

- machine de production de carrière

- le processus dextraction du sable de silice

- chine ciment fabricant de l unite de broyage abon

- clinker technologies de broyage

- excavation de mine à long

- devis pour meuleuse

- machine d introduction de broyeur boulets

- bien dans lextraction de bauxite

- charbon machine concasseur mobile a vendre inde